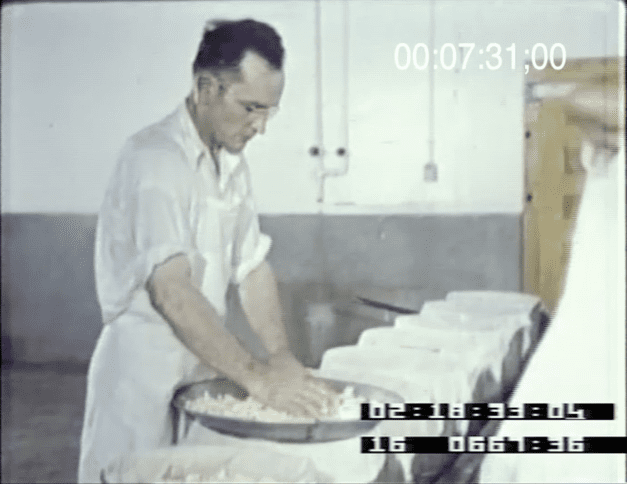

Moulding the cheese

After the cheese has rested for one hour in the vat, it is poured into moulds. A finely woven cloth called cheesecloth is then used to line the inside of the metal moulds. The curds are placed inside and compacted by hand. The cheese wheels are then covered with a wooden disc, and are laid on the side. The lever of the manual cylinder is then activated in order to press the cheese and expel the air and the whey until the wheels reach 30 cm high.

ContinueC1.5